Capacity Planning is a useful tool for scheduling jobs in order to comply with terms while avoiding an overload of existing resources. Using this tool the production manager is able to automatically allocate and schedule the work on every machine with respect to capacity loads, to standard and/or special routings and other variables. Manual schedule and plan can be carried out as well: by means of a very easy to use Gantt diagram all tasks and operations can be shifted in time or assigned to different machines.

Capacity Planning is directly integrated into Opty-Way Enterprise to allow all users to quickly answer the FAQ (Frequently Asked Question) “when my order would be ready?”” Production forecasting and scheduling can be performed since order entry phase with respect to actual, locked, free and up to date schedule.

Functionality

- Planner defines what it is to be done, where it is to be done, when it is to be done.

- Start and End date of each operation is the result of scheduling.

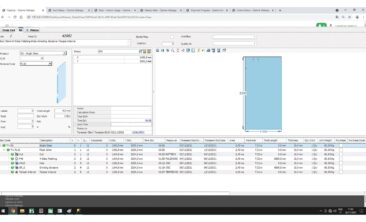

- Very easy to use interface for production plan overview and edit

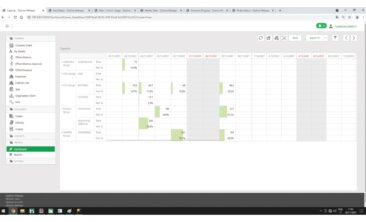

- Gantt graph displays the task and the operation below time scale

- Capacity and work loads are shown on the Histogram graph

- Different planning strategies available: ASAP, JIT

- Different loading strategies available: most loaded, least loaded, Sequential

- Capacity loads can be expressed in time as well as production units (m2, ml, etc.)

- Machines can be included into group of resources

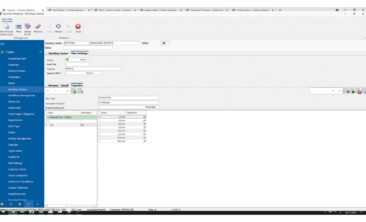

- Each machine has its own calendar with different timetables

- Possibility to define different capacity for each day/turn

- Possibility to define variable capacity depending on properties of glass and jobs (shapes, mat. Type, etc.)

- Planner can “lock” an operation to a date and to a machine